The E1 message notifies about a failure or incorrect operation of the fuel delivery system.

|

Possible cause of failure: |

Procedure: |

|

Air pressure too low |

Air pump adjustment (adjustment screw on the rear pump housing) |

|

Fuel level too low |

Refilling the fuel tank |

|

Dirty air filters |

Cleaning, preferably filter replacement |

|

Fuel nozzle dirty |

Clean or replace the nozzle |

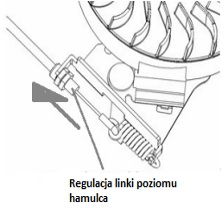

The first oil change in a new mower should take place after the engine has been running for 5 hours. Each subsequent replacement should occur once per season or every 25-35 hours, whichever comes first.

Replacement is recommended first and is the most important as it removes any metal particles remaining from the engine after its assembly. Changing the oil regularly helps keep your lawn mower engine in good condition, ensuring performance and long life.

ATTENTION!!! New John Gardener mowers are not filled with oil, you must top up the oil before using them for the first time!

What oil for a lawn mower?

Use 4-stroke or 10W-40 engine oil

1. An insufficient amount of air supplied to the engine may weaken the engine of a petrol lawn mower, which causes carbon deposits to accumulate.

Insufficient air may be caused by the throttle not opening properly while the unit is operating, resulting in incomplete combustion of gasoline. Long-term operation in this way accelerates the accumulation of carbon deposits in the combustion chamber. The solution is to check the proper operation of the carburettor throttle and the throttle lever on the handle. Make sure they are completely open.

2. Also, a clogged air filter leads to reduced air intake and results in incomplete fuel combustion. Dust and dirt also clog the air filter. Another possible cause may be a filter element saturated with engine oil. You should then clean the air filter and carburettor with pressurized air or clean gasoline and then start the mower at high speed so that the remaining carburettor dirt can be flushed out.

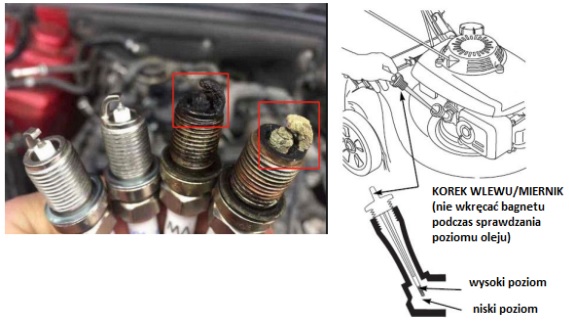

3. Please note that excessive engine oil or mowing the grass at an angle will allow a large amount of oil to enter the combustion chamber, causing severe carbon build-up on the spark plug. Then check the spark plug for contamination. If the spark plug is dirty, it should be cleaned of accumulated carbon deposits or replaced. Then check the engine oil level and make sure it is in proper condition. After performing the above-described activities, start the device at high speed and let the mower work for 1-2 minutes.

4. Loose ignition wires cause unstable ignition. The position of the nut should be adjusted to ensure proper cable tension.

5. Loose valves or excessive valve clearance. Symptoms of such a fault may include regular crackling noises in the running engine. Check and adjust the valve valve clearance (intake valve 0.06-0.07; exhaust valve 0.07-0.09). 6. Leaks from the cylinder head, manifest themselves as oil leaking around the head cover. Remove the lower cylinder head, clean and replace the gasket. After cleaning, adjust the valves according to the previous parameters.

6. Leaks from the cylinder head, manifest themselves as oil leaking around the head cover. Remove the lower cylinder head, clean and replace the gasket. After cleaning, adjust the valves according to the previous parameters.

7. Deformation of the adjuster spring due to impact or bending. This results in reduced mower speed and insufficient engine power. Check and adjust the engine speed with the adjustment screw to set the mower speed to approximately 2800-3000 rpm.

8. Damage to the flywheel wedge is caused by hitting a stone or a solid element protruding from the mowed grass. This contributes to the misalignment of the ignition timing. Then the mower does not start or you can hear cracking and popping sounds from the carburetor during operation. The key on the shaft should be replaced and the flywheel should be adjusted accordingly.

|

Possible cause of failure: |

Procedure: |

|

Out of fuel |

Refilling the tank |

|

Dirty filter |

Clean/replace filter |

|

No spark, damaged spark plug |

Replacing the spark plug with a new one |

|

No spark, too weak throttle cable tension |

Adjusting the throttle cable |

When selecting a generator for your devices, you should take into account, among others:

Power types:

Type of receivers according to the type of received power:

The power rating of each device should be listed on the device nameplate. This power is given in the unit of active power - kW (kilowatts). When selecting a generator, add up the power of single-phase and three-phase receivers. You should select a generator with a power that exceeds the total power of the receivers.

Single-phase generator

If we only have single-phase devices, you can purchase a single-phase generator, without a three-phase socket.

When selecting the generator, additional power oversizing should be used, e.g. for resistive and non-linear receivers, the power demand of the generator must be at least 1.2 times greater than the rated power of the device. For induction receivers, the power requirement is at least 3 times higher than the rated power of the device. The reason for this oversizing is the starting currents. For example, the power consumed when starting an electric motor can be approximately 2 to 4 times greater than its nominal power requirement during continuous operation.

Example:

Three-phase generator

If we decide on a generator that will be able to connect both single-phase and three-phase devices, we should choose a generator that has single-phase and three-phase sockets.

When selecting power-powered devices, the following conversion factors should be used:

Three-phase motor electric:

In the case of an electric motor, check its starting current and select the appropriate generator power.

Heating equipment:

Lighting:

UPS Power:

Electrical appliances: